Our Factory

The Care We Take Over Our Factory

Hikari Foods released a sauce onto the market that contains no artificial food additives in 1964, followed by another sauce made with organic ingredients in 1977. Ever since then, we have been committed to using safe and organic ingredients to make foods that truly are the real thing, and contain no additives.

Having acquired the organic JAS certification for our factory in 2000, we do not simply aim for efficiency, and rather than going fully automatic, still do some of the processes manually. In this way, we continue to create products that still retain that hand-made goodness, never compromising, and sparing no effort.

The basic rule is that the production tanks are washed by hand with hot water, and the main filling line has a CIP cleaning system to perform thorough washing to ensure there is no contamination by allergens and so on.

The walls and ceilings of the production room, bottle-cleaning room, filling room, packaging room, and storage tank room are all stainless steel, creating an extremely hygienic manufacturing environment.

Some rooms are kept at positive pressure to prevent insects from entering, and the filling room is a clean room. Multiple cameras are installed inside the factory for traceability and food safety.

Our manufacturing processes have been managed in accordance with HACCP for a long time, and in February 2020, we acquired the international food safety management system certification FSSC 22000. (Manufacture of heat treated sauces and seasonings including processed tomato products packed in glass bottles, plastic containers and cans. Manufacture of heat treated fruit juice concentrates in glass bottles. Manufacture of dried and powdered raw materials made from vegetables and fruits. Exclusions apply : Diced carrots and garlics for OEM products.)

FSSC 713500 / FSSC 22000

The production control ensures that records are kept in a wide range of manufacturing processes. In addition to having a production system that meets the HACCAP standards, we also take food safety measures that are made visible in accordance with global standards, in order to make our foods more safely than ever.

光食品自昭和39(1964)年發售無合成添加物的醬汁,之後在昭和52(1977)年發售使用有機原料的醬汁以來,一直堅持使用安全的原料而不使用添加物,製造使用有機原材料、真材實料的食品。

2000年工廠獲有機JAS認證。工廠不僅追求工作效率,更不妥協也不惜麻煩,不選用全自動化,而是保留手製的優點製造產品。

製造缸的清洗基本為用熱水進行手洗,主力的充填生產線選用CIP清洗,以避免混入過敏原等。

製造室、洗瓶室、充填室、包裝室、缸暫存室的天花板和牆都使用不鏽鋼,製造環境非常衛生。

工廠內保持正壓以防止蟲的入侵,充填室採用無塵室設計。另外,工廠內設有監控,提升可追溯性和食品安全防護。

製造工序按一直沿用HACCP管理,而在2020年2月,獲得FSSC22000。(FSSC22000取得範圍:Manufacture of heat treated sauces and seasonings including processed tomato products packed in glass bottles, plastic containers and cans. Manufacture of heat treated fruit juice concentrates in glass bottles. Manufacture of dried and powdered raw materials made from vegetables and fruits. Exclusions apply : Diced carrots and garlics for OEM products.)

透過在各製造工序留下記錄的管理方式,加上基於HACCAP的生產體制,以及按照國際標準的可視化食品安全對策,製造最安心、安全的食品。

The Facilities in Our Factory

|

Vegetable Washing Room / 蔬菜清洗室

Some of the raw materials, such as vegetables produced on our own farms, are cleaned and processed in our factory. Vegetables are washed in a separate area from the production room, etc., in order to prevent soil bacteria and insects from getting into the factory. 清洗及加工自家農園產的蔬菜等部分原料。為避免工廠內受土壤微生物或蟲等的入侵,位置與製造室等相隔。 |

|

|

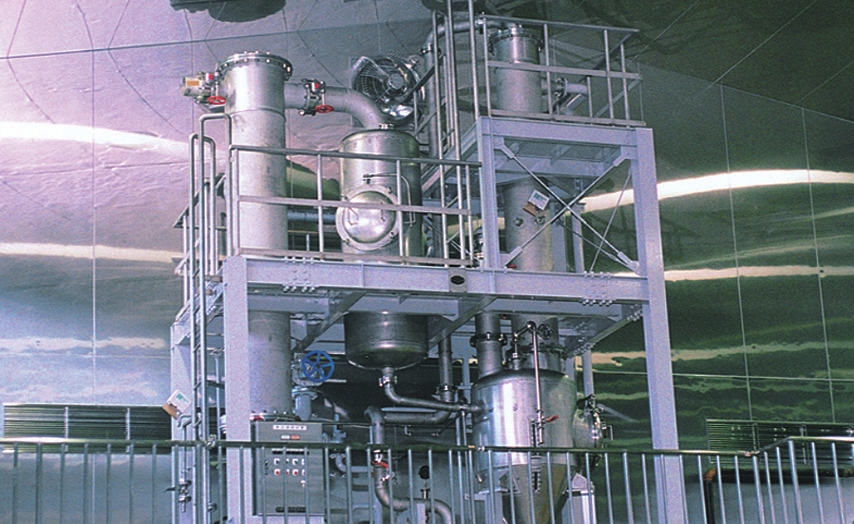

Vacuum Concentrator / 真空濃縮機

The equipment installed includes a liquid downward flow vacuum concentrator. This enables us to make tomato puree from tomatoes without using any additives, and at a lower temperature so less heating is required. 設有將番茄製造成蕃茄泥時,無需使用添加劑,而且低溫以減輕熱負荷的液體流下型真空濃縮裝置等。 |

|

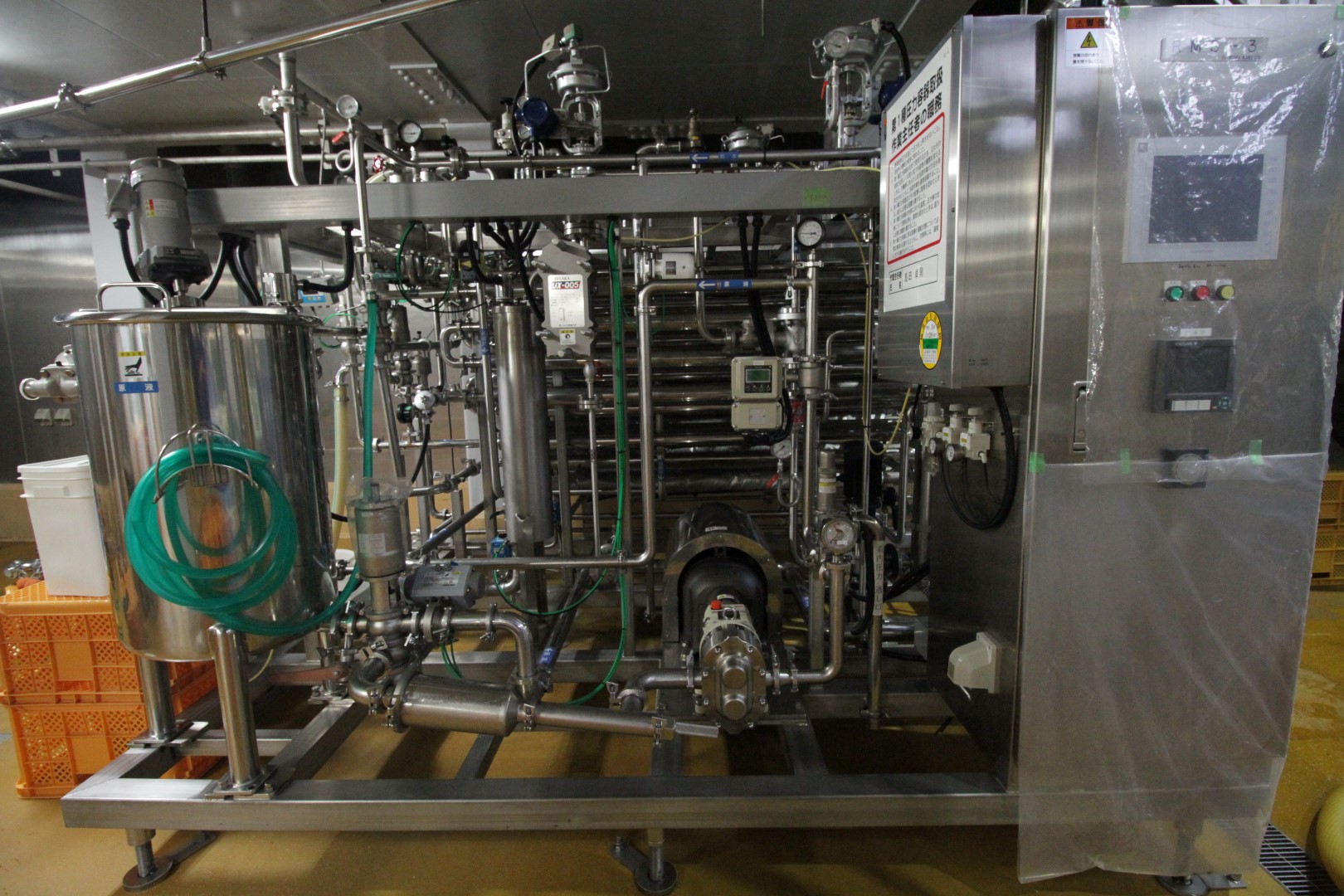

Flash Pasteurizer (Tubular Pasteurizer) / 瞬間殺菌裝置(加熱管)

In order to pasteurize heat-resistant bacteria, etc. without compromising the flavor of the raw materials, we use a tubular pasteurizer to sterilize in a flash. 能在儘可能不影響原料風味的前提下,使用加熱管把溫度瞬間提升,對具備耐熱性的細菌等進行殺菌。 |

|

Bottle-Cleaning Room / 洗瓶室

Empty bottles are cleaned and sterilized with hot water only and no chemicals, etc. 不使用藥品,只用熱水清洗空瓶並殺菌。 |

|

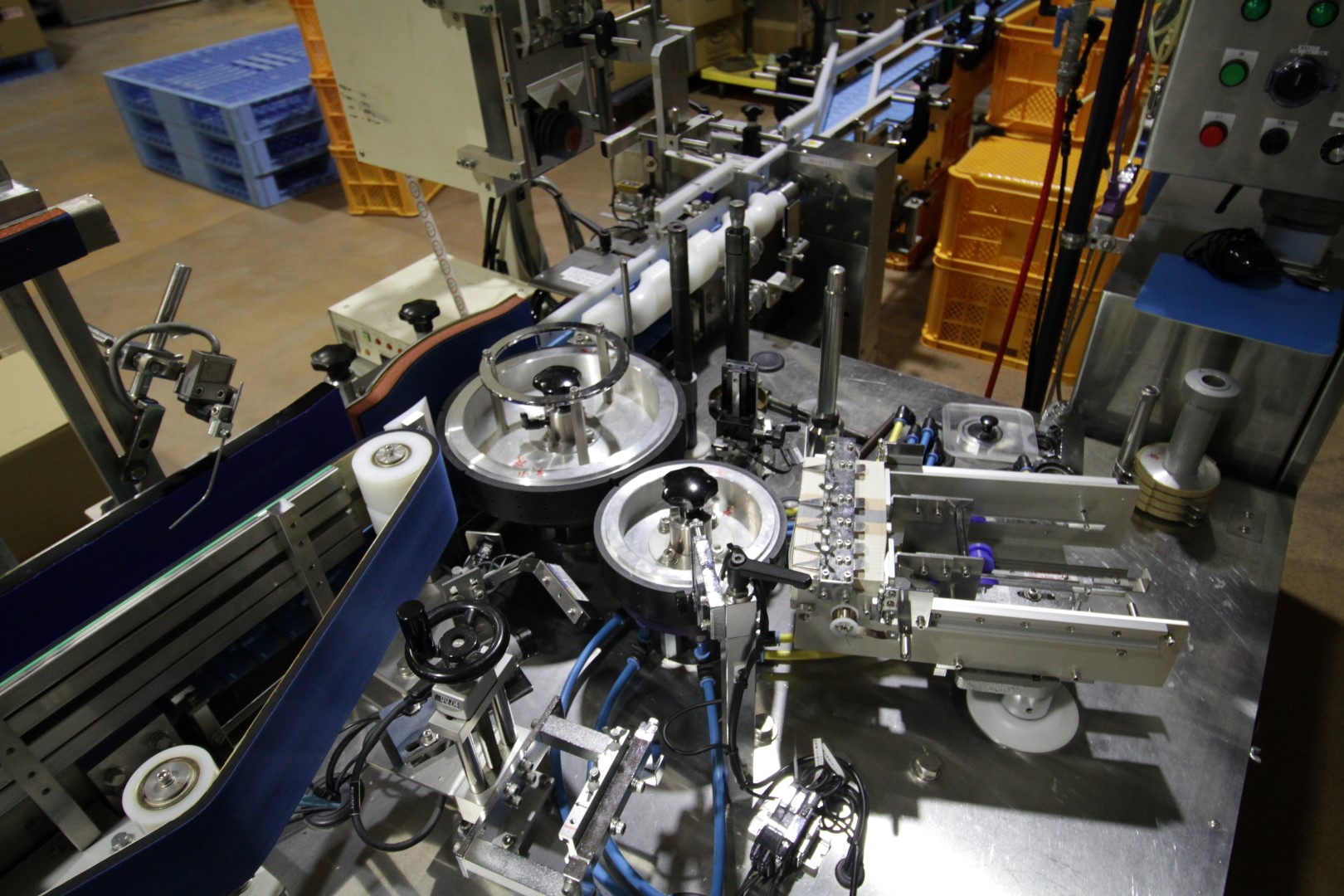

Empty Bottle Inspection Machine / 空瓶檢查機

We have introduced an inspection machine that instantly detects flaws or stains on the top surface of empty bottles through image analysis, and can reject bottles and store image data on them at the same time. This enables us to detect minor scratches, etc. not visible to the human eye, and to fill the bottles with products more safely than ever before. 投入以圖像分析,能瞬間測出空瓶的瓶口有否受損或黏有污跡,並能將其去除及保存相關數據的檢查機。使用這台檢查機能發現肉眼看不見的微細傷痕等,使產品的充填能在比以往都更安全的狀態下進行。 |

|

Filler / 充填機

The filling room is a clean room. When the containers are being filled, foreign objects are removed using physical or magnetic filters.The main filler fills each bottle, weighs it, and keeps a record. For screw cap bottles, the force applied to close the cap is controlled and recorded for each bottle. 充填室是清潔的無塵室,充填時使用過濾機及磁性濾網去除異物。主力的充填機為每瓶產品測重及充填,並保留該記錄。充填機制御每瓶旋蓋瓶產品的扭蓋扭力,並保留該記錄。 |

|

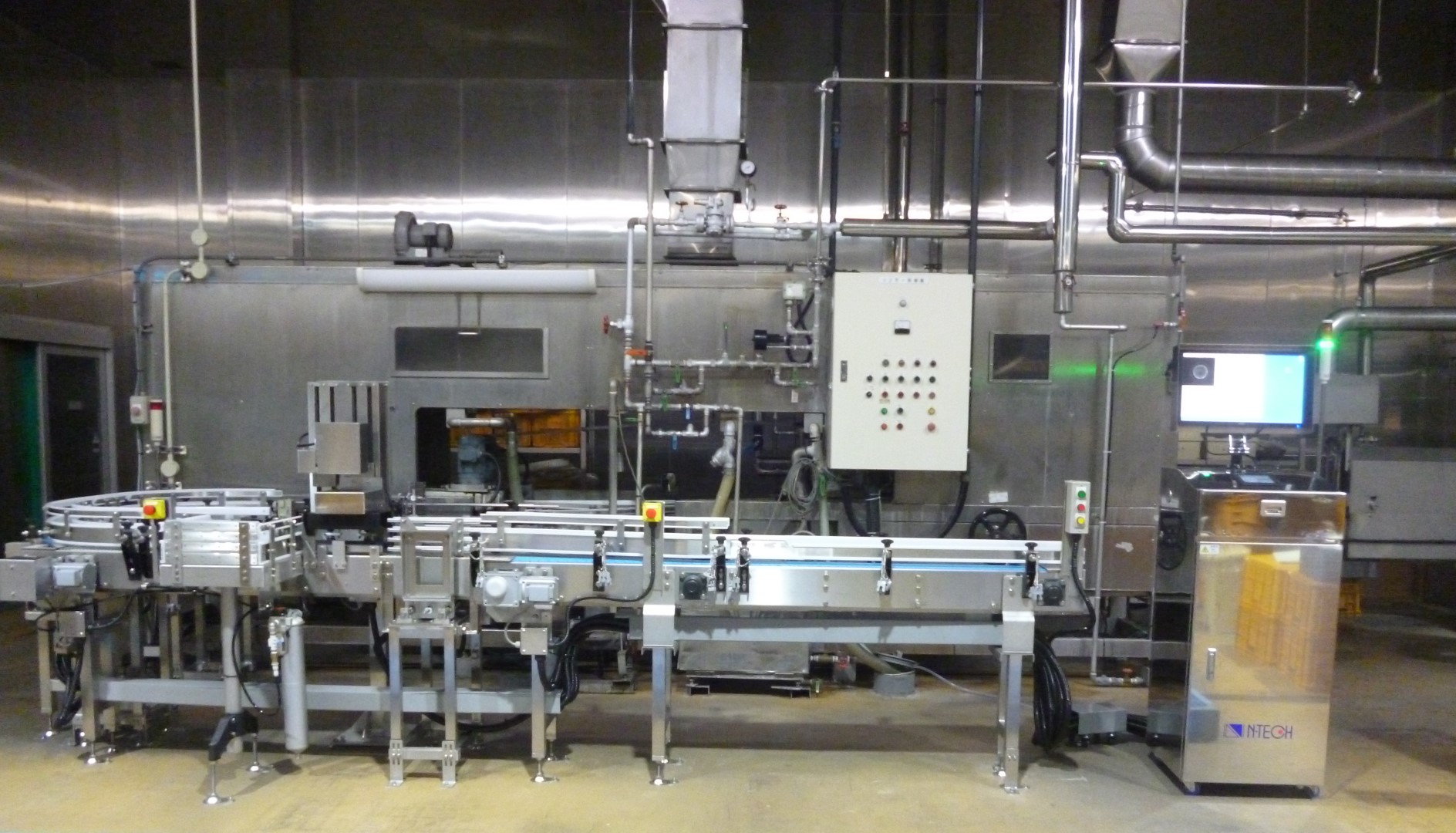

CIP Cleaning System / CIP清洗裝置

In order to prevent contamination by allergens, the main filler line is equipped with a CIP cleaning system. This enables the inside of the pipes to be cleaned without disassembling the line. 為避免混入過敏原,主力充填生產線附有CIP清洗裝置,無需拆開生產線便能清洗管道內部。 |

|

Packaging Room / 包裝室

In order to prevent printing defects when labeling or wrapping with film, the main labeler uses a camera to inspect what has been printed, and in the event of a defect, rejects the product and keep a record of it. 在張貼標示或包覆捆膜時,為避免有效期限的印刷出現不良,主力貼標機設有檢查印字內容的鏡頭,如有不良則會自動去除並保留該記錄。 |